A Journey through the New Exquisito Chocolates

Update: Exquisito Chocolates is now open for business Thurs.-Fri. 11-6 and Sat. 11-7.

When we last heard from Carolina Quijano about her new chocolate factory, she had just won first place in the Food Innovation Pitch Night last October after sharing her goals to expand her small bean-to-bar chocolate company into a storefront in Little Havana. She had been selling her chocolate and cocoa online, at events and to Miami-area businesses. Now, she had her eyes set on growing.

Six months later, that dream is a reality. Quijano is opening the doors of Exquisito Chocolate on the west end of Calle Ocho in the building where a mural by Atomik welcomes visitors to Little Havana. Inside her minimalist lobby, there's cacao art and images of the cacao plantations where she sources her beans.

Behind big windows is the factory where the chocolate is made.

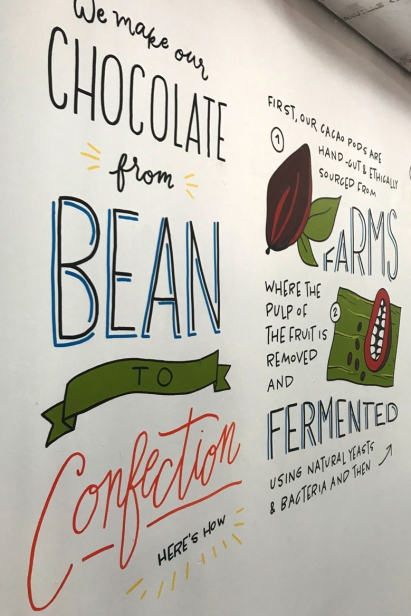

A whimsical mural explains the process of turning mottled brown cacao beans into silky-smooth chocolate bars. Quijano is there to talk visitors through every step of the process, even handing them goggles to get a closer look at the Central American farms where she sources her cacao.

Not all chocolate makers let the public watch the process, but Quijano has designed her space with tours in mind. "I want people to be able to come into the shop and ask questions about what and why we do this and have the answers for them, so that they see us as true artisans also committed to bettering the industry as a whole," she says. "When I first started out I used to offer free bean-to-bar demos in order to educate people about where chocolate comes from, and to help me make chocolate in an effort to learn. I noticed early on that chocolate is very familiar, but there's a huge disconnect for people as to what it is and where it comes from."

The Chocolate Tour

Quijano designed her open factory concept so that people can see exactly each step in the process. At a recent preview, she took visitors on a chocolate journey.

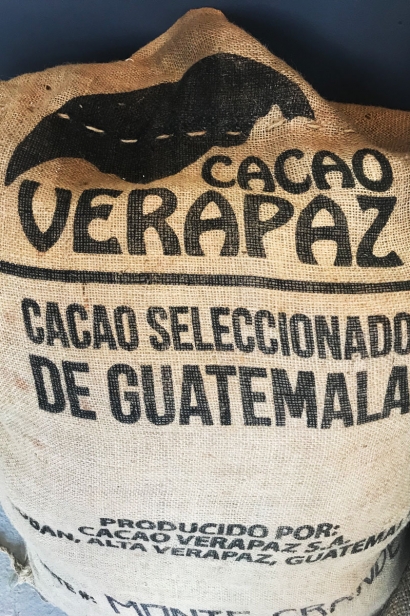

First is the ethical sourcing of the chocolate. She insists upon using cacao, harvested by workers who are paid a fair wage, from family farms, but has moved from a fair trade and organic certified model to direct sourcing.

"So far we have cacao from Dominican Republic, Ecuador, Peru, Colombia, Haiti, Guatemala – two farms in different regions. I've also previously bought from Venezuela, Mexico and Bolivia," she says. "Cutting out all the middlemen I could allowed me to have a more direct source to understanding what I was buying and developing relationships with agronomists, farmers and importers in order to have greater quality control assurance." This allows her to better contribute financially to what the farmer ultimately receives, she says. "I truly believe farmer prosperity is a key ingredient in making great chocolate, so knowing that they are getting paid above-market prices for their work is essential and better seen with this model. Long-term, as the business grows and we have more financial access, I'd love to use that direct connection to help invest in social programs for farmers and their families – education, business courses, etc."

Step-by-Step to Cacao Production

The road to making chocolate starts on the farm, where ripe cacao pods are hand cut from the trees. The juicy pulp and beans inside the pods are fermented in boxes under banana leaves and the beans are set out in the sun to dry. They are then delivered to the chocolate maker in big burlap bags, on display in Exquisito’s lobby.

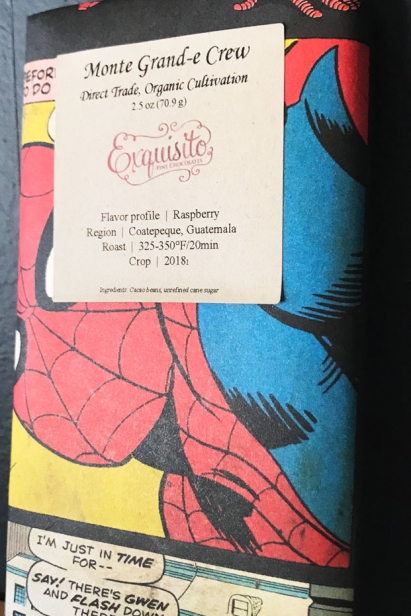

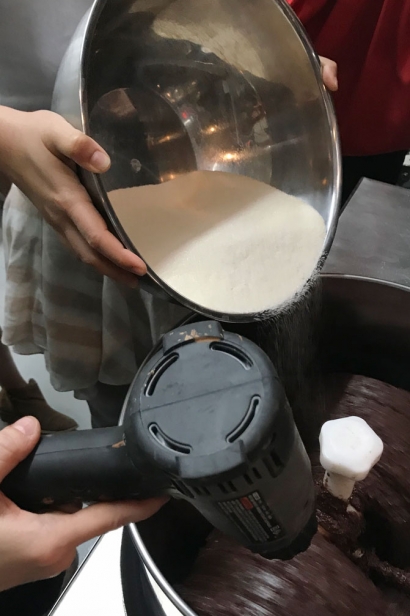

From here, the bean-to-bar chocolate maker takes over. The cacao beans are roasted on trays for specified times and temperatures, the recipe carefully noted because these factors affect the flavor of the chocolate. The beans are then manually sorted for imperfections, before being cracked and winnowed, a process to remove their thin shells.

For this, Exquisito uses a piece of equipment that’s cobbled together from parts that include a juicer, a shop vac and a network of PVC pipes. (On a smaller scale, a hair dryer could be used to blow away the papery husks). Quijano explains that for small-batch chocolate makers, this set-up is the norm.

"The winnower is composed of a hopper, the big steel bucket up top to hold the cacao; a Champion juicer that breaks beans; a vacuum chamber, a big box with PVC tubes that is attached to a Shop Vac; the husk bin where the husks drop; and the nib outlet, where nibs came out from and into bucket," she says. "A lot of small-batch chocolate makers rely on using equipment that is not used for its intended purpose. The chocolate machine industry is just trying to catch up to the growing industry as they notice a market need. The lack of equipment is to me a clear reflection of how heavily monopolized chocolate has been for decades – you're either a massive company or non-existent."

Quijano says most small craft makers owe their start to the "Godfather" of chocolate, a retired chemist named Jon Nanci of Chocolate Alchemy. "He's been the one to come up with machines like the winnower I own. My favorite part is that he isn't even that fond of chocolate, but loves the idea of disrupting a static industry."

From Nibs to Silky Smooth Chocolate

After winnowing, the nibs are fed into an industrial-sized grinder – like an enormous food processor – and worked into a chunky cacao paste that is melted. This coarse mixture is mixed with sugar, heated and added into the melanger. In this motorized device, granite slabs and rollers rotate to further grind and where it is ground for hours until it turns shiny and smooth.

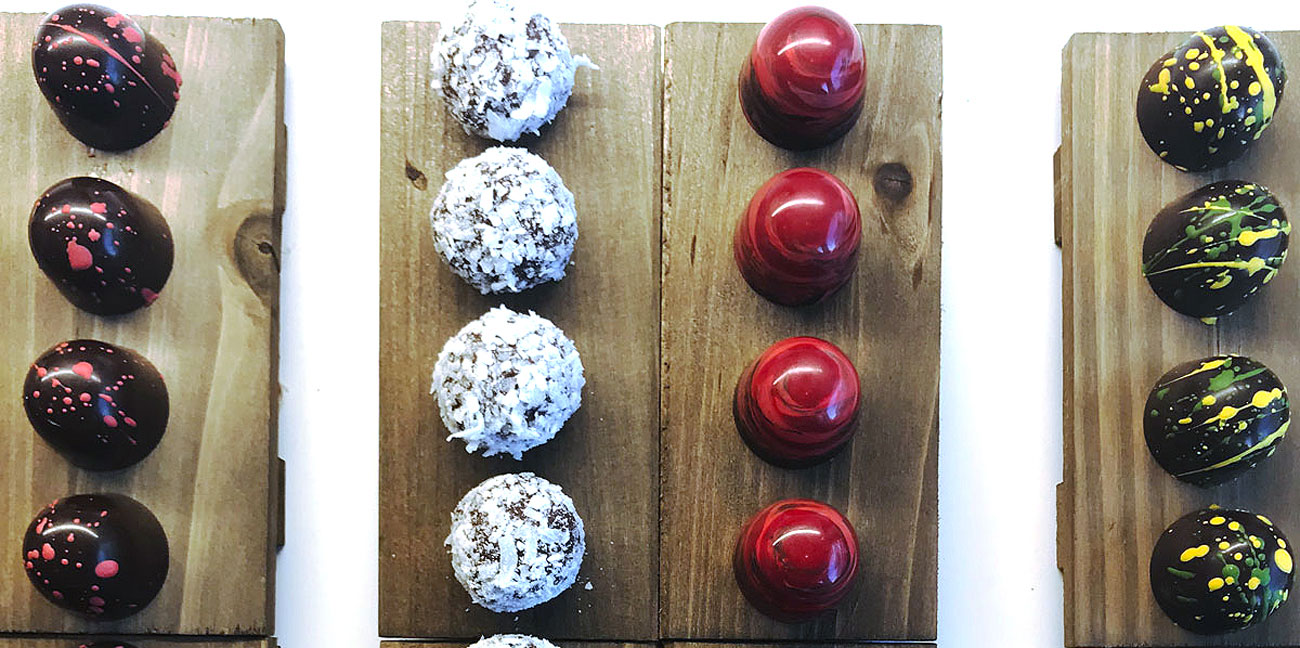

The chocolate is strained into tubs for later use. The final step before making bonbons, truffles and other candies is tempering – melting, cooling and handling so that it remains glossy and smooth and snaps when you bite into it. It takes four days to make a single batch of chocolate from freshly roasted cocoa beans, says Quijano.

What About Taste?

For many accustomed to overly sweet, inexpensive candy bars made with lots of additives, the taste of unadulterated chocolate may be surprising. "'Wow! So, this is what chocolate tastes like. I had no idea!' is typically the reaction I get from people used to commercial chocolate," Quijano says, noting that she has increased the cocoa percentages in her chocolate since opening. "I initially started out with a 62% base and have now upped it to 73% as a result of people really enjoying the flavor of pure chocolate. Our milk chocolate has also moved up from 45% to 63%." Some who say they don't like dark chocolate because they think it's bitter based on past experiences are also changing their mind, she says. "We've been poorly trained that dark chocolate is bitter because that is what we get from mass chocolate. Since that's not the profile of the chocolate we produce, we get a lot of positive remarks."

They've also won awards from the Academy of Chocolate in London, she says. "We were recognized for our Monte Grande bar farmed by Antonio Conde, the young farmer on the bar wall, and our cognac truffle ("Henny for your Thoughts") and Cafe con Leche truffle made with Per'La Roasters espresso."

Exquisito Chocolate is available to the public for tours. They also offer tours for private groups and businesses, says Quijano, who came out of the finance world. "I love using my love for chocolate and background in management consulting to bridge the two and help companies see how they too can think of innovative ways to push their ideas forward. The retail is available to just buy our products."

EXQUISITO CHOCOLATES

2606 SW 8th St., Little Havana

exquisitochocolates.com

Open Thurs.-Fri. 11-6 and Sat. 11-7. Exquisito Chocolates are used in Miami restaurants, including Azucar Ice Cream in Little Havana, Threefold Cafe and others, and in a special beer at Lincoln's Beard Brewing.